Titanium and its alloys are very durable materials, yet ductile and soft what makes them hard to machine. Low density and thermal conductivity make cutting materials greatly overheat during the process. Machined material may join or adhere to the cutting tools.

Significant differences between titanium and steel (or nickel based alloys)

It is important to note the most important differences between titanium and steel (or nickel based alloys). Titanium shows the following properties:

- has a lower density,

- has lower elasticity modulus,

- is less ductile,

- is vulnerable to contamination during welding.

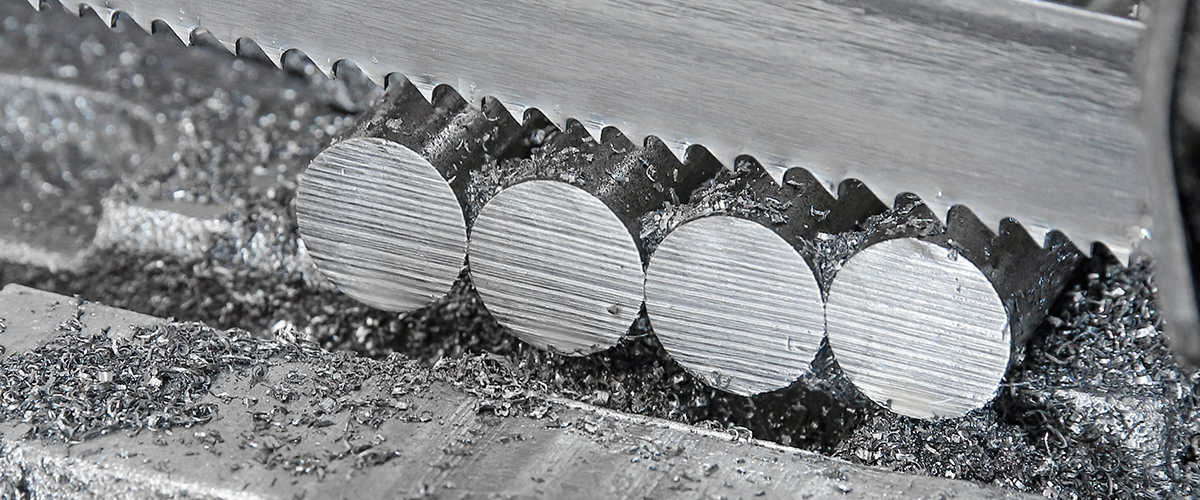

For machining, it is suggested to use low working speed tools along with a large amount of coolant. Also, machining could turn to be complicated due to the fact that during cutting, titanium forms swarfs, which can get wrap around cutting tools. Elasticity of titanium alloy, very demanded in a finished elements, could cause bends and vibrations during machining. Elastic element bends during machining, making the cutting tools edges rub the element instead of cutting it.

For milling and stamping,it is suggested to use high-speed alloys (i.e. tungsten carbide) or stellites. During the process, make sure that titanium swarfs don’t adhere to each other.

Other articles

Norms and standards of non-ferrous metal products

All non-ferrous metal products offered by WOLFTEN are manufactured according to specific standards. Clearly defined technical standards guarantee the homogeneity of the materials used, which directly affects the specific characteristics of each structure and their safety.

Sustainable environmental technologies and metallurgy

Can metallurgy be considered a sustainable environmental technology? This is the question that bothers not only environmental activists, but anybody concerned with the mining industry having a considerable impact on the natural environment.

Neural networks in metallurgy

Ability to develop, create and apply a specific material marks the border between business success or failure. Forecasting mechanical properties of a new alloy is an important aspect for both scientists and engineers as it allows saving time and money.