TITANIUM

We specialize in materials such as titanium – we provide products of all grades. Our offer includes bars, pipes, sheets, flat bars, foils, strips and fasteners as well as spherical powders for 3D printing.

Titanium products we offer

About Ti

Ti is a lustrous transition metal with low density (light weight), good thermal conductivity and a low Young modulus value, with melting point at 1725°C. It’s a chemical element with the symbol Ti and atomic number 22, discovered by William Gregor in Cornwall in 1791. It owes its name to the Titans of Greek mythology – the pre-Olympian gods, children of the primordial parents Uranus (Sky) and Gaia (Earth).

Characteristics

Pure, unalloyed metal is used primarily in applications where high corrosion resistance is required, such as production of chemical equipment or off-shore drilling.

Depending on the concentration of interstitial elements, Ti shows good ductility and machinability. These properties, along with good corrosion and creep resistance, make titanium very popular across many applications.

HIGH

ENDURANCE

Titanium shows a high level of mechanical endurance and hardness

OSSEOINTEGRATION

Titanium is the most biocompatible metal due to it’s resistance to corrosion by bodily fluids

CORROSION

RESISTANCE

Titanium exhibits high brine and chloride corrosion resistance, making it a very popular material across many industries

Ti6Al4V alloy is commonly used in aviation and space industries as a building component of propulsion systems or structural elements of the fuselage. It is also used to manufacture golf clubs, surgical implants and medical devices, shuttles for weaving machines and, due to brine resistance, parts of boats and yachts. In machinery and equipment engineering, this alloy finds its use in production of elements exposed to high dynamic loads. It could be used to cast turbine heat shields, rotating at 600 m/s and operating in temperatures up to 300° C.

Titanium is considered to be the most biocompatible metal due to its resistance to corrosion caused by bodily fluids, bio-indifference, high fatigue strength and osseointegration. Ability to withstand difficult conditions in the human body is owed to a protective, oxidized layer naturally developed in the presence of oxygen in body fluids. This insoluble and impenetrable oxidized layer adjoins the tissue and prevents chemical reactions with the environment. The mechanical properties and the loading conditions in the host have greatly influenced the selection of this material for various clinical applications.

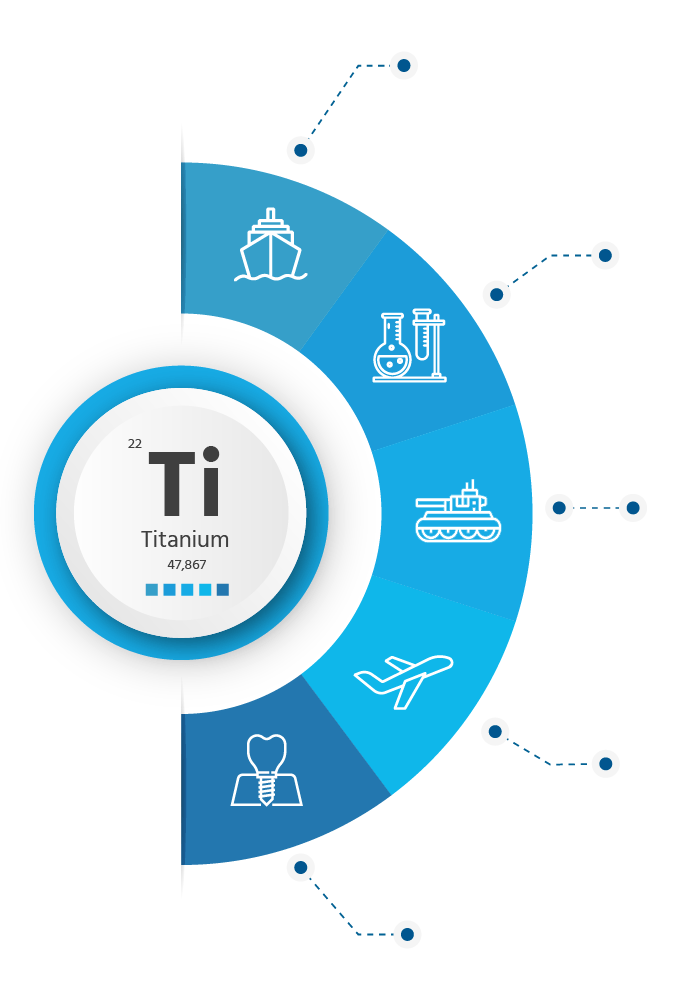

Usage and applications

Titanium can no longer be considered as an exotic, expensive or hard to obtain material. The usage of this metal is very broad and, as technological development progresses, becomes even broader.

SHIP BUILDING INDUSTRY

ship or boat hulls, elements of the watertight watercrafts’ bodies

CHEMICAL INDUSTRY

piping systems, tanks and reactors

MILITARY INDUSTRY

elements of armor and kinetic energy protection

AVIATION INDUSTRY

aircraft fuselage, fasteners (bolts, screws, pins), wing structural elements, engine parts (fan blades, compressors).

BIOMEDICAL ENGINEERING

dental implants, orthopedic prostheses

Titanium grades and alloys

Titanium grades differ from each other in composition, mechanical properties and range of applications. Titanium grades 1 to 4 are grades of commercially pure titanium (99,2%). They can be both cold- and hot- molded.

GRADE 1

Titanium Grade 1 shows a high level of deformability, used to manufacture embossed elements

GRADE 2

Titanium Grade 2 makes 70% of titanium sales, has a very broad range of applications: from medical through chemical purposes.

GRADE 3 AND 4

Titanium Grade 3 and Titanium Grade 4 are used, among other applications, in electroplating for spring fixation or other elements used during anodizing.

GRADE 5

Titanium Grade 5 (Ti6Al4V) is utilized mainly in aviation, due to its high strength; Composition of Ti6Al4V alloy makes 90% titanium, 6% aluminum, 4% vanadium.

GRADE 5 ELI (23)

Popular mainly for medical applications. It’s an alloy composing of less oxygen, nitrogen and carbon in comparison to Grade 5.

GRADE 6

Popular for military applications, i.e. cockpit window frames, torsion boxes, connectors or wherever the substantial strength in high temperatures is required.

GRADE 7

An alloy with the addition of palladium (0,12-0,25%), is used in chemical processes. Palladium increases the corrosion resistance in comparison to Grade 2.

GRADE 9

Titanium Grade 9 (Ti-3Al-2.5V) is used for bike frames, paraglide elements and other extreme sports equipment. Decreasing the amount of alloying elements increases its formability. Chemical composition of Ti-3Al-2.5V alloy makes 90% titanium, 3,0% aluminum, 2,5% vanadium

GRADE 12

The addition of nickel and molybdenum increases corrosion resistance and decreases susceptibility to crevice corrosion, especially in chloride environments. It’s ideal for shell and tube heat exchangers. Finds broad application in chemical industry.

Ti-6Al-Nb

A recently-developed alloy acting as a replacement for alpha-beta Ti6-Al4V alloy, developed in 1977. A cytotoxic vanadium, hitherto utilized as a clinically used implant material has become replaced by niobium, which shows no influence on biological tissue.

Military specification – Titanium and titanium alloys(Sheet – Strip – Plate) |

|||

MIL-T-9046H |

MIL-T-9046J AMENDMENT-2 (1991) |

||

| Type I | Commercially Pure Titanium | Commercially Pure Titanium | |

| (CP) | (CP) | ||

| Comp A – Unalloyed (40 KSI-YS) | Code designation | ||

| Comp B – Unalloyed (70 KSI-YS) | CP-1 | (70 KSI-YS) | |

| Comp C – Unalloyed (55 KSI-YS) | CP-2 | (55 KSI-YS) | |

| CP-3 | (40 KSI-YS) | ||

| CP-4 | (30 KSI-YS) | ||

| Type II | Alpha Titanium Alloy | Alpha Titanium Alloys (A) | |

| Comp A – 5Al-2.5Sn | Code Designation | Composition | |

| Comp F – 8Al-1Mo-1V | A-2 | 5Al-2.5Sn (ELI) | |

| Comp G – 6Al-2CG-1Ta-0.8Mo | A-3 | 6Al-2Cb-1Ta-0.8Mo | |

| A-4 | 8Al-1Mo-1V | ||

| Type III | Alpha-Beta Titanium Alloy | Alpha-Beta Titanium Alloy | |

| Comp C – 6Al-4V | (AB) | ||

| Comp D – 6Al-4V ELI | Code designation | Composition | |

| Comp E – 6Al-6V-2Sn | AB-1 | 6Al-4V | |

| Comp G – 6Al-2Sn-4Zr-2Mo | AB-2 | 6Al-4V (ELI) | |

| Comp H – 6Al-4V SPL | AB-3 | 6Al-4V-2Sn | |

| AB-4 | 6Al-2Sn-4Zr-2Mo | ||

| AB-5 | 3Al-2.5V | ||

| AB-6 | 8Mn | ||

| Type IV | Beta Titanium Alloys | Beta Titanium Alloys (B) | |

| A 13V-11Cr-3Al | Code Designation | Composition | |

| B 11.5Mo-6Zr-4.5Sn | B-1 | 13V-11Cr-3Al | |

| C 3Al-8V-6Cr-4Mp 4Zr | B-2 | 11.5Mo-6Zr-4.5Sn | |

| D 8Mo-8V-2Fe-3Al | B-3 | 3Al-8V-6Cr-4Mo-4Zr | |

| B-4 | 8Mo-8V-2Fe-2Al | ||

| CONDITION CODE | DESCRIPTION |

| A | Annealed |

| DA | Duplex annealed |

| TA | Triplex annealed |

| ST | Solution treated |

| STA | Solution treated & aged |

Why WOLFTEN?

- We offer commercially pure titanium as well as titanium alloys.

- We supply wires, bars, electrodes, cylinders, plates, sheets, flat bars, screws, bolts, washers and other fasteners.

- We deliver titanium and titanium alloy products of any size and grade, as per customers’ requirements and demands.

- We are open to long-term and close cooperation – for those ordering regularly, we keep the stock levels for products and elements to be available on the spot for specific installations and manufacturing processes.

- We guarantee fast and effective, yet flexible deliveries, including smaller quantities. We utilize the just-in-time inventory management strategy.

- Our products are based on ASTM standards (American Society for Testing and Materials). All components and products offered by Wolften, are manufactured according to ASTM standards.

- Additionally, we stock bars certified for various applications, including those for aviation industry (AMS), medical, military (MIL) and high-pressure purposes (ASME).